Why Multi-Axis Machining Is Shaping Aerospace Manufacturing

Table Of Contents

Challenges in Adopting Multi-Axis Machining

Adopting multi-axis machining can present significant hurdles for aerospace manufacturers, particularly when aligning existing workflows with new technologies. A common challenge lies in the need for a comprehensive understanding of complex geometries and machining processes. For instance, transitioning from traditional three-axis to five-axis machining requires operators to develop skills that include proficient programming and setup execution. Many organizations report a steep learning curve, leading to initial productivity dips as teams adjust to the advanced equipment and its capabilities.

Integration of software tools poses another layer of complexity. Many machining manufacturers face difficulties in implementing CAD/CAM solutions effectively. Outdated software may lead to inefficiencies in design precision, causing bottlenecks and increasing production costs. A survey from the National Association of Manufacturers indicates that over 40% of companies struggle to bridge the gap between design and manufacturing, often resulting in a mismatch between the intended design specifications and the final product. Investing in advanced software training and maintaining up-to-date technological resources can mitigate these challenges while enhancing overall operational effectiveness.

What Are Common Pitfalls and How to Avoid Them?

One common pitfall in multi-axis machining is inadequate training of operators. Research indicates that approximately 30% of production errors stem from human factors. Properly qualified operators possess a deep understanding of machine capabilities. Investing in comprehensive training can significantly enhance productivity and reduce costly mistakes. A machining manufacturer should evaluate the skill levels of its workforce before integrating complex multi-axis equipment.

Another critical challenge arises from insufficient software integration. Many machining manufacturers overlook the impact of using out-of-date or incompatible software tools, which can lead to inefficiencies and design flaws. For instance, using CAD software that doesn't fully support multi-axis simulations can result in errors that propagate through the manufacturing process. Adopting software solutions that are optimized for multi-axis machining ensures that designs are executed accurately, reducing the likelihood of rework or scrap due to mistakes.

Role of Software in Multi-Axis Machining

Advanced software plays a crucial role in enhancing the precision and efficiency of multi-axis machining processes. Programming the complex movements required for 5-axis machines relies heavily on sophisticated algorithms. These algorithms not only optimize tool paths but also reduce machining time, ultimately maximizing productivity. For instance, software tools like Mastercam and SolidWorks streamline the toolpath generation, significantly decreasing the lead time for aerospace components. A machining manufacturer utilizing these platforms can experience reductions in cycle times by as much as 30%, allowing for faster production cycles.

Furthermore, these software solutions integrate seamlessly with computer-aided design (CAD) systems, facilitating real-time adjustments and modifications. This integration supports rapid prototyping and enables manufacturers to respond quickly to engineering changes. The ability to simulate machining processes virtually reduces the risk of errors, leading to higher-quality outputs. One case study from an aerospace supplier reported a 50% decrease in scrap rates after implementing this software-driven approach. Enhanced design precision mitigates the likelihood of costly reworks and rejections, emphasizing the importance of investing in robust software capabilities for cutting-edge aerospace manufacturing.

How Can Advanced Software Improve Design Precision?

Advanced software plays a crucial role in enhancing design precision within multi-axis machining processes. A study conducted by a leading machining manufacturer found that utilizing sophisticated CAD/CAM software can reduce design errors by up to 30%. Software tools equipped with simulation capabilities allow engineers to visualize complex geometries before physical machining begins, eliminating costly adjustments during production. These systems enable teams to analyze the impact of tool paths and machining strategies, ensuring that deviations from desired specifications are identified and addressed early in the design phase.

Furthermore, integrating software that adheres to industry standards, such as AS9100 for aerospace quality management, ensures that all machining practices maintain precision and consistency. Data-driven approaches, like using real-time feedback from tools and operational metrics, further enhance the design iteration process. Manufacturers leveraging predictive analytics can anticipate potential issues, allowing engineers to refine designs proactively. Utilizing platforms that combine both CAD and CAM functionalities streamlines the transition from design to production, ultimately leading to improved product quality and reduced lead times.

Case Studies of Multi-Axis Machining in Aerospace

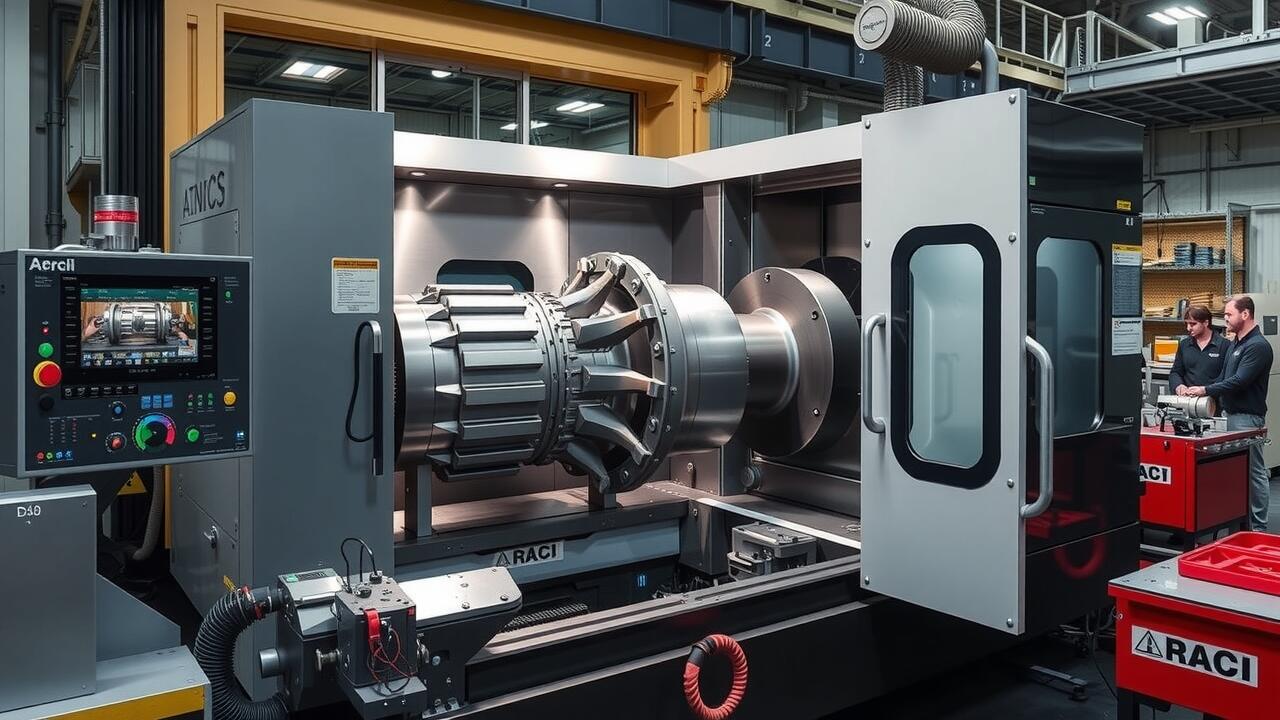

Multi-axis machining has been instrumental in achieving precision and efficiency within aerospace manufacturing. A notable example comes from Boeing, which has successfully implemented five-axis machining to produce complex components like the wing structures of the 787 Dreamliner. The integration of this technology allowed the machining manufacturer to reduce production times by 30% while enhancing dimensional accuracy. Such advancements facilitate the creation of intricate geometries that are crucial for aerodynamics, ultimately leading to lighter and more fuel-efficient aircraft.

Another case study involves Lockheed Martin's F-35 program, where advanced multi-axis machines handle components with tight tolerances essential for military aircraft. The deployment of sophisticated machining techniques has led to a reduction in assembly time by 25%, showcasing the capability of multi-axis machining to streamline operations while meeting stringent aerospace regulations. Companies that adopt similar methodologies can expect not only a faster turnaround but also greater versatility in designing complex parts. Continuous investments in technology and training will be vital for sustaining these advancements in the competitive aerospace landscape.

What Success Stories Highlight Its Effectiveness?

One notable success story in multi-axis machining emerged from Boeing's use of this technology in producing complex aerospace components. By implementing five-axis machining for manufacturing critical engine parts, Boeing improved production efficiency by over 30%. This approach not only enhanced precision but also reduced lead times significantly. The ability to machine intricate geometries in one setup minimizes the need for multiple re-fixturing operations, leading to greater accuracy and reduced risk of human error, aligning with industry standards for safety and performance.

Another compelling example comes from an aerospace machining manufacturer that faced challenges with traditional machining methods for crafting turbine blades. By integrating multi-axis capabilities, the manufacturer achieved a remarkable 25% reduction in machining time while improving surface finish quality by 15%. The recent adoption of advanced toolpath strategies not only streamlined the production process but also allowed for the handling of innovative geometries that traditional methods could not accommodate. This case underscores the critical role of embracing technological advancements in the aerospace sector to meet increasing demands for efficiency and precision.

Future-Proofing Aerospace Manufacturing with Multi-Axis Techniques

The rapid evolution of aerospace manufacturing necessitates a strong focus on continuous improvement through the incorporation of multi-axis machining techniques. By integrating these advanced methods, organizations are better positioned to respond to the rigorous demands of precision and efficiency. For instance, a machining manufacturer that upgrades to five-axis systems can achieve up to 30% faster production times while significantly reducing material waste compared to traditional three-axis methods. This not only enhances output but also aligns with industry sustainability goals.

Investing in multi-axis techniques can propel a company forward, ensuring compliance with increasingly stringent aerospace regulations. For example, a prominent aerospace company noted a 25% reduction in labor costs after implementing automated multi-axis machining processes. By embracing ongoing training and adapting workforce skills to evolving technologies, manufacturers can maintain competitiveness in a global market. Establishing such standards fosters an environment of innovation while providing a foundation for scalability and adaptability in future production cycles.

Why Is Continuous Improvement Important in Machining Processes?

Continuous improvement plays a crucial role in machining processes, particularly for aerospace applications where precision and reliability are paramount. Aerospace components often require intricate geometries and tight tolerances; even minor defects can result in significant safety concerns. A machining manufacturer that prioritizes continuous improvement typically employs methodologies like Lean and Six Sigma, which help identify inefficiencies and reduce waste. For instance, aerospace companies reported a reduction in cycle times by up to 20% after implementing these methodologies, proving that ongoing evaluation leads to better outcomes.

Moreover, continuous improvement fosters innovation by encouraging teams to re-evaluate their workflows regularly. Regular feedback loops and performance metrics enable manufacturers to adapt quickly to changes in technology or market demands. By implementing advanced monitoring technologies, such as real-time data analytics, companies can gain insights into machine performance and product quality. These adjustments not only enhance production efficiency but also ensure that the manufacturing processes meet or exceed industry standards, ultimately elevating the entire aerospace supply chain.

FAQS

What is multi-axis machining?

Multi-axis machining refers to a manufacturing process that utilizes multiple axes of movement to create complex parts with high precision and efficiency. This technique is particularly useful in industries such as aerospace, where intricate designs are often required.

What challenges do manufacturers face when adopting multi-axis machining?

Some common challenges include the high initial investment in machinery and software, the need for specialized training for operators, and potential difficulties in integrating new systems with existing manufacturing processes.

How can advanced software improve the precision of multi-axis machining?

Advanced software enhances design precision by providing sophisticated simulation tools, enabling better tool path optimization, and allowing for real-time monitoring and adjustments during machining, which ultimately leads to higher accuracy and reduced waste.

What are some success stories of multi-axis machining in the aerospace industry?

Success stories include cases where aerospace manufacturers have significantly reduced lead times and production costs by implementing multi-axis machining, as well as instances of achieving complex geometries that were previously impossible with traditional machining methods.

Why is continuous improvement important in machining processes?

Continuous improvement is crucial for enhancing efficiency, reducing costs, and maintaining competitiveness in aerospace manufacturing. Regularly refining machining processes allows manufacturers to adapt to new technologies, improve product quality, and respond to changing industry demands.